The Black Soldier Fly (BSF) industry has reached a crossroads in 2026. On one side, we see backyard enthusiasts; on the other, $50 million "Giga-factories." But the most significant growth is happening in the "Missing Middle"—professional, mid-sized facilities processing 10 to 50 tons of organic waste per month.

At this scale, you need a cold grasp of your Capital Expenditure (Capex) and Operating Expenditure (Opex). If you are planning to scale up this year, here is the financial and biological blueprint for a standard 20-ton-per-month (input) facility module.

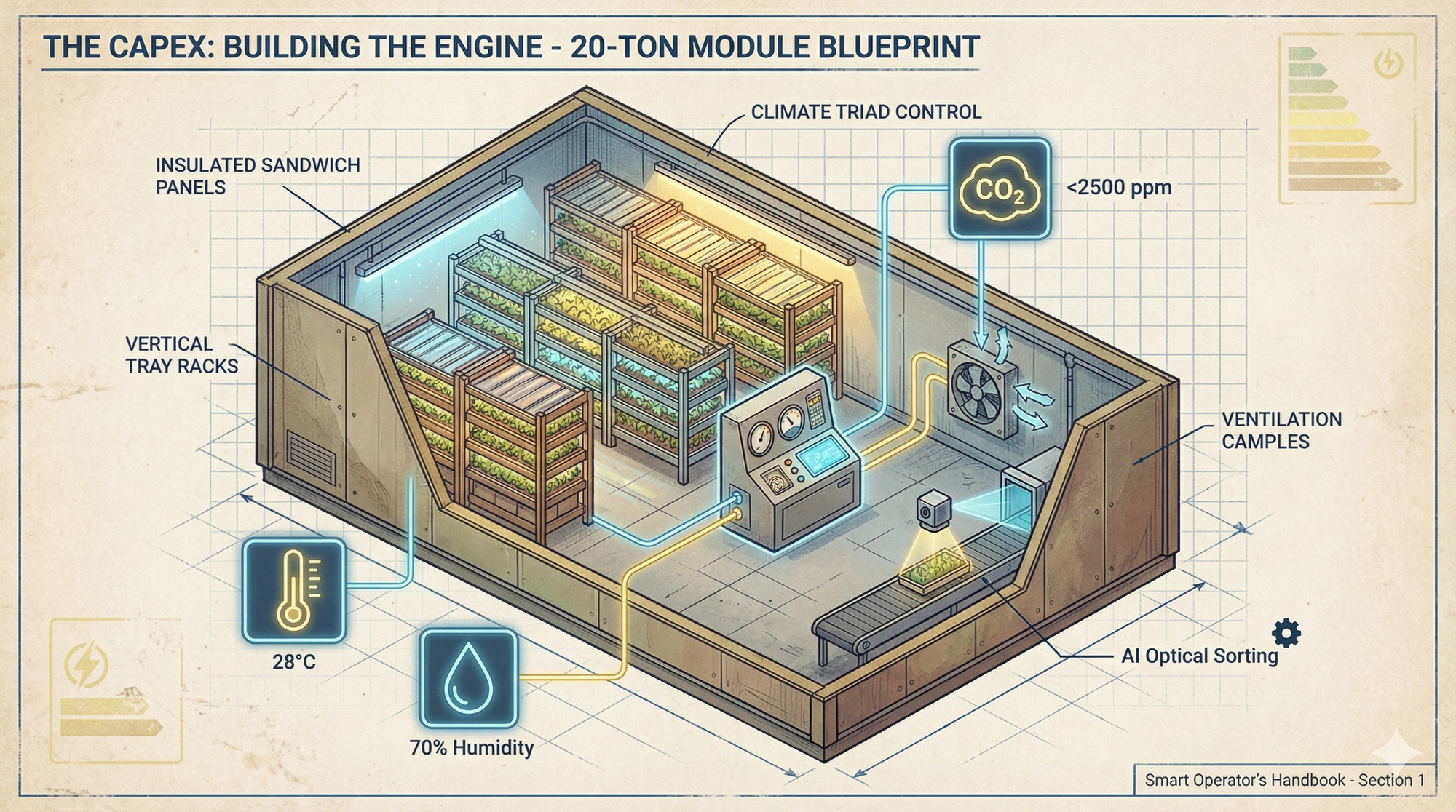

1. The Capex: Building the Engine

Capex is your "Foundational Burn"—the one-time cost to get the doors open. In 2026, the trend has shifted toward "climate-resilient modularity."

A. Infrastructure & Climate ($45,000 - $65,000)

To hit 20 tons a month, you can no longer rely on ambient weather.

- The Structure: Insulated sandwich-panel units are the 2026 standard for thermal stability.

- The "Triad" of Automation: Modern HVAC systems no longer just track temperature (28°C) and humidity (70%). To maximize larval health, you must now integrate CO2 monitoring.

- The Bio-Metric: Keeping CO2 levels below 2,500 ppm is critical. High CO2 triggers "larval crawl-out" (escape) and significantly reduces feeding rates, leading to stunted growth cycles.

B. The Bioconversion Hardware ($25,000 - $35,000)

- The Tray System: Vertical farming is the only way to make the footprint viable.

- Digital Sampling: AI-driven optical sorting reduces sampling and density estimation time by up to 70%, allowing for highly precise feed-rate adjustments.

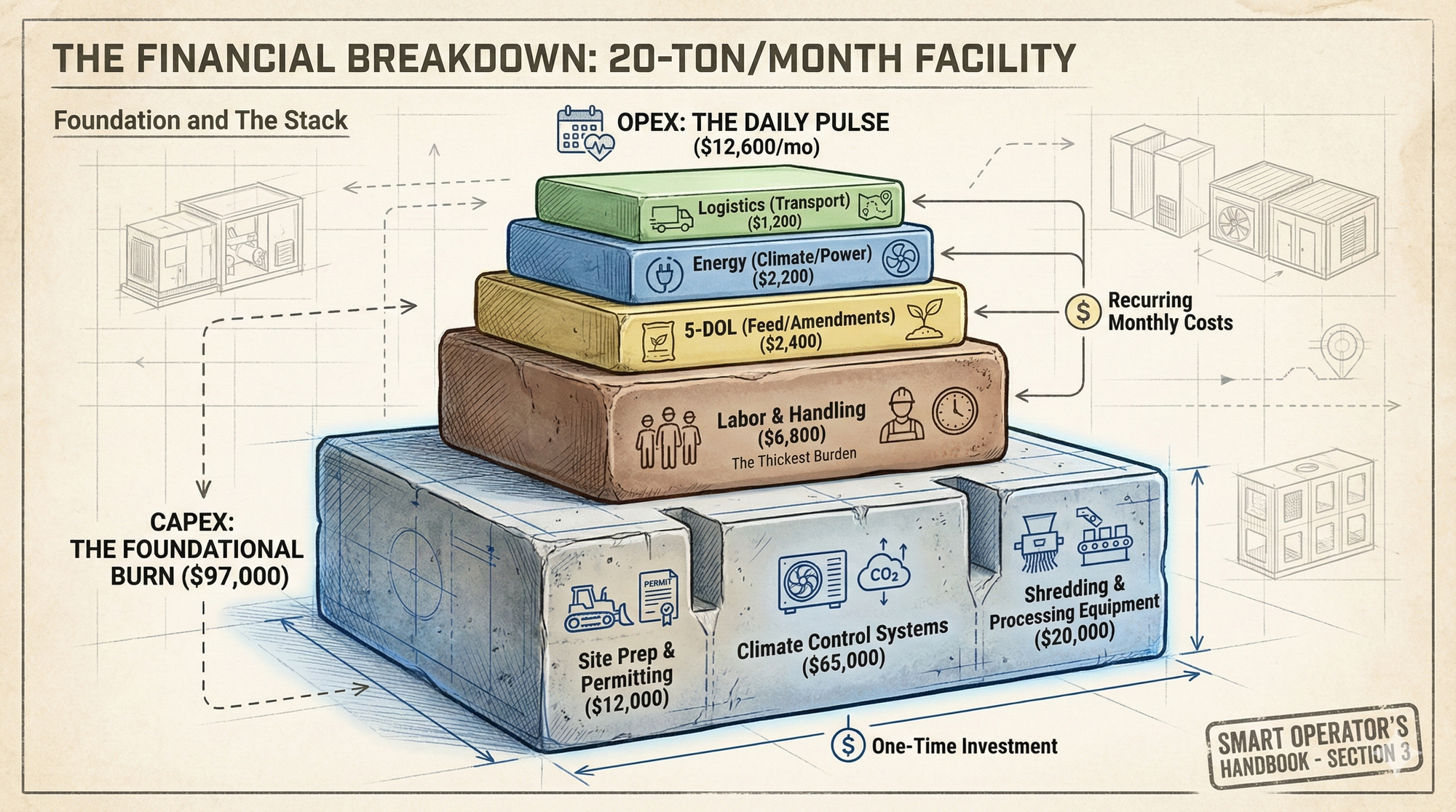

2. The Opex: The Daily Pulse

Opex is your "Daily Pulse." If your Opex is too high, you are buying your way into a deficit with every cycle.

A. The Feedstock Competition

In 2026, competition for high-quality, pre-consumer waste (spent grain, fruit pulp) is fierce. Most mid-sized facilities should baseline for a Net-Zero Feedstock Cost. While some land gate-fee contracts, professional-grade larvae usually require you to pay a nominal fee ($10–$30/ton) for traceable, clean inputs.

B. The "Handling Tax"

Labor is the "silent killer" of BSF startups.

The 2026 Efficiency Target: To remain competitive, your facility design should strive for 12–18 man-hours per ton of dry output. Most manual mid-sized start-ups begin at 40+ hours; reducing this through layout optimization and modular flow is your fastest path to protecting your margin. Every unnecessary manual tray movement costs you approximately $0.04/kg of finished product.

3. The Financial Breakdown: Single 20-Ton/Month Module

Note: Figures are 2026 averages. Labor costs reflect the need for semi-skilled technical oversight.

| Category | Item | Estimated Cost (USD) |

| Capex | Site Prep & Insulated Modular Housing | $55,000 |

| Capex | Climate Control (HVAC + CO2 Scrubbing) | $14,000 |

| Capex | Shredding & Processing Equipment | $28,000 |

| TOTAL CAPEX | $97,000 | |

| Opex (Monthly) | Energy (HVAC & Industrial Drying) | $1,800 |

| Opex (Monthly) | 5-DOL (Purchasing 5-Day-Old Larvae)* | $2,500 |

| Opex (Monthly) | Labor (2-3 Technicians @ 2026 rates) | $6,800 |

| Opex (Monthly) | Logistics & Feedstock Acquisition | $1,500 |

| TOTAL OPEX | $12,600/mo |

*Strategic Note: Mid-scale operators are increasingly purchasing 5-DOL to outsource the biological risk and Capex of an in-house nursery.

4. Summary: ROI & Scaling Strategy

Success in 2026 isn't just about growing bugs—it's about managing the "burn" versus the "pulse."

The Reality of Scaling:

While a single 20-ton module serves as the critical proof-of-concept, true profitability and the 20–26 month ROI target are typically realized when 3–4 of these modules are clustered. This allow for labor, management, and processing equipment costs to be shared across a much larger output volume, drastically lowering your cost-per-kg.

Claim Your 2026 BSF Growth Toolkit

Don't leave your infrastructure to guesswork. We have bundled our most requested operational resources into a single Growth Toolkit to help you bypass the "Missing Middle" hurdles.

Inside the 2026 Toolkit:

- The 15-Point Site Readiness Checklist: A technical audit for ventilation, drainage, and CO2 extraction.

- The "Build vs. Buy" Decision Matrix: A strategic guide on outsourcing your nursery.

- The 20-Ton/Month Budget Baseline: Updated 2026 figures for labor, energy, and certified protein pricing.